The Prospect Hydro Electric Project

Download PDF version of this case study

Independent testing of DuraShield coated steel pipe revealed that even after prolonged exposure to harsh atmospheric elements, its protective coating didn’t deteriorate at all. LifeLast’s DuraShield polyurethane coatings offer the best penstock steel pipe protection available.

AWWA C222 industry standard compliant for interior and exterior steel water pipe.

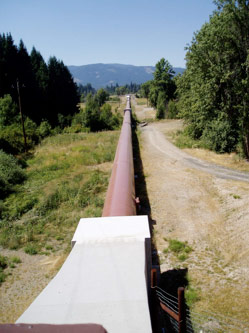

Penstock pipe heading to the powerhouse

The PacifiCorp Prospect Hydroelectric Project is located in Jackson County, Oregon on the Rogue River and two of its tributaries, near the town of Prospect. Lands abutting the project include those owned by the U.S. Forest Service, state of Oregon, Boise Cascade, PacifiCorp, and other private landowners.

Original construction took place between 1911 and 1946 by the California–Oregon Power Company (Copco). Copco subsequently merged with Pacific Power and Light Company in 1961. Since then, the project has been owned and managed by PacifiCorp with additional phases added. It includes three concrete diversion dams, three powerhouses, and a water conveyance system of approximately 9.3 miles. The entire hydroelectric system is a run-of-the-river operation.

In a two-phase construction cycle from 2004 to 2005, PacifiCorp added 2,070 lineal feet of 96” and 2,200 lineal feet of 78” penstock pipe to the system. The pipe was produced at the Northwest Pipe Company’s Portland, Oregon facility, lined with 20 mils and coated with 25 mils of LifeLast DuraShield 210. The pipeline was top coated with 3 mils of aliphatic polyurethane to ensure color stability on the above ground sections.

LifeLast DuraShield polyurethanes are ideal for penstock applications due to the physical properties they demonstrate. A combination of excellent adhesion

to the substrate, superior abrasion and impact resistance and low coefficient of friction* make DuraShield polyurethanes the industry choice for penstock corrosion protection.

78” welded steel pipe installation

As a part of our customer’s quality assurance process, a section of The Prospect Penstock pipe was evaluated for coating adhesion after 27 months of atmospheric exposure. The test results show atmospheric

exposure had no effect on the DuraShield system’s ability to perform under direct exposure conditions.

Ask for a copy of our independent testing performed by The Utah Water Research Laboratory – “Friction Test on 48” Polyurethane-Lined Steel Pipe” – May 2007

Questions or technical assistance on your specification or project?

Contact us; we’re happy to help. Email us at info@LifeLast.com

or call (512) 628.2112.